Industrial washing / Articles

Rack washers: what is it, how it works and how to pick one

Discover how rack washers redefine industrial washing with powerful performance, ease of use, and cost-saving benefits. Learn how to choose the right one.

22 minutes of reading

22 minutes of reading

2024-10-31 15:24:55

Rack washers aren’t just a convenience. They’re a critical line of defense against contamination. Without them, even the most meticulously maintained racks become breeding grounds for grease, oil, and dirt. These contaminants can easily transfer to stored items, leading to quality issues, damaged reputation, or, in worst cases, costly product recalls.

Manual cleaning is time-consuming, and often misses hard-to-reach areas, leaving risks behind. Rack washers, on the other hand, are highly automated systems designed to clean racks of all sizes thoroughly and efficiently, using less water, energy, and labor. But with so many models and configurations available, how do you choose the right one? Here’s what you need to know.

What is a rack washer?

A rack washer is a type of industrial washing machine specifically designed to wash and sanitize racks, trays, carts, and similar items commonly used in sectors such as food processing, healthcare, and pharmaceuticals. These machines are purpose-built to accommodate the unique dimensions and materials of industrial transport and storage equipment, ensuring thorough cleaning without damaging sensitive components.

Unlike standard dishwashers or manual washing setups, rack washers are engineered for continuous, high-throughput environments where hygiene and efficiency are critical. They are typically integrated into workflows where hygiene is a regulatory and operational necessity, making them essential in settings governed by strict sanitation standards.

While the term may seem broad, it refers to a very specific category of equipment with clearly defined applications. A rack washer is not a general-purpose washing unit; it is a dedicated solution designed to support hygiene-critical operations by automating the washing of bulky, reusable handling equipment.

The advantages of rack washers

What really makes rack washers stand out? Here are some key advantages:

Efficiency at scale

Rack washers are built for high-volume operations, allowing businesses to wash a large number of items in a single cycle. Instead of washing individual racks or trays manually, you can load them all at once, significantly speeding up the cleaning process. This time-saving feature is crucial in industries where equipment needs to be ready for use as quickly as possible. By handling more items per wash, these machines help teams work more efficiently, reducing downtime and allowing staff to focus on other important tasks.

Thorough washing

Rack washers are designed to tackle the toughest dirt and residue, ensuring that every item gets a complete and thorough wash. The machine’s high-pressure water jets and targeted spraying system reach every corner, even those that are hard to wash by hand. This is essential for industries like healthcare and food services. With a rack washer, you can trust that even the most stubborn grime or contaminants will be fully removed, leaving everything spotless and safe for use.

Cost savings

Even though a rack washer might seem like a big investment, the savings over time more than make up for it. These machines reduce the need for labour-intensive manual washing, freeing up your team for other tasks. Additionally, they are designed to use water and detergent efficiently, cutting down on utility and supply costs. In the long run, the operational savings, coupled with the reduced need for replacement washing equipment, make rack washers a smart financial decision.

Built-in sustainability

For many organisations, sustainability targets are now part of daily operations, compliance frameworks and even customer expectations. In high-demand environments, hygiene is critical, but that doesn’t mean it has to come at the cost of efficiency or the environment.

A modern rack washer makes it easier to meet internal and external sustainability goals. Thanks to smart systems (like filtered water recirculation, automated dosing and intelligent load detection) the machine optimises every wash, using only what’s strictly necessary. This minimises waste across the board: less pre-rinsing, fewer chemicals, lower consumption. In short, real, measurable contribution to your environmental goals and ESG reporting.

Improved hygiene

In industries where hygiene is non-negotiable, rack washers help you maintain the highest standards. These machines are engineered to meet strict health and safety requirements, ensuring that every wash meets your industry’s sanitation protocols. High temperature washing cycles and powerful rinsing systems eliminate harmful bacteria and contaminants, making sure your equipment is ready for immediate use.

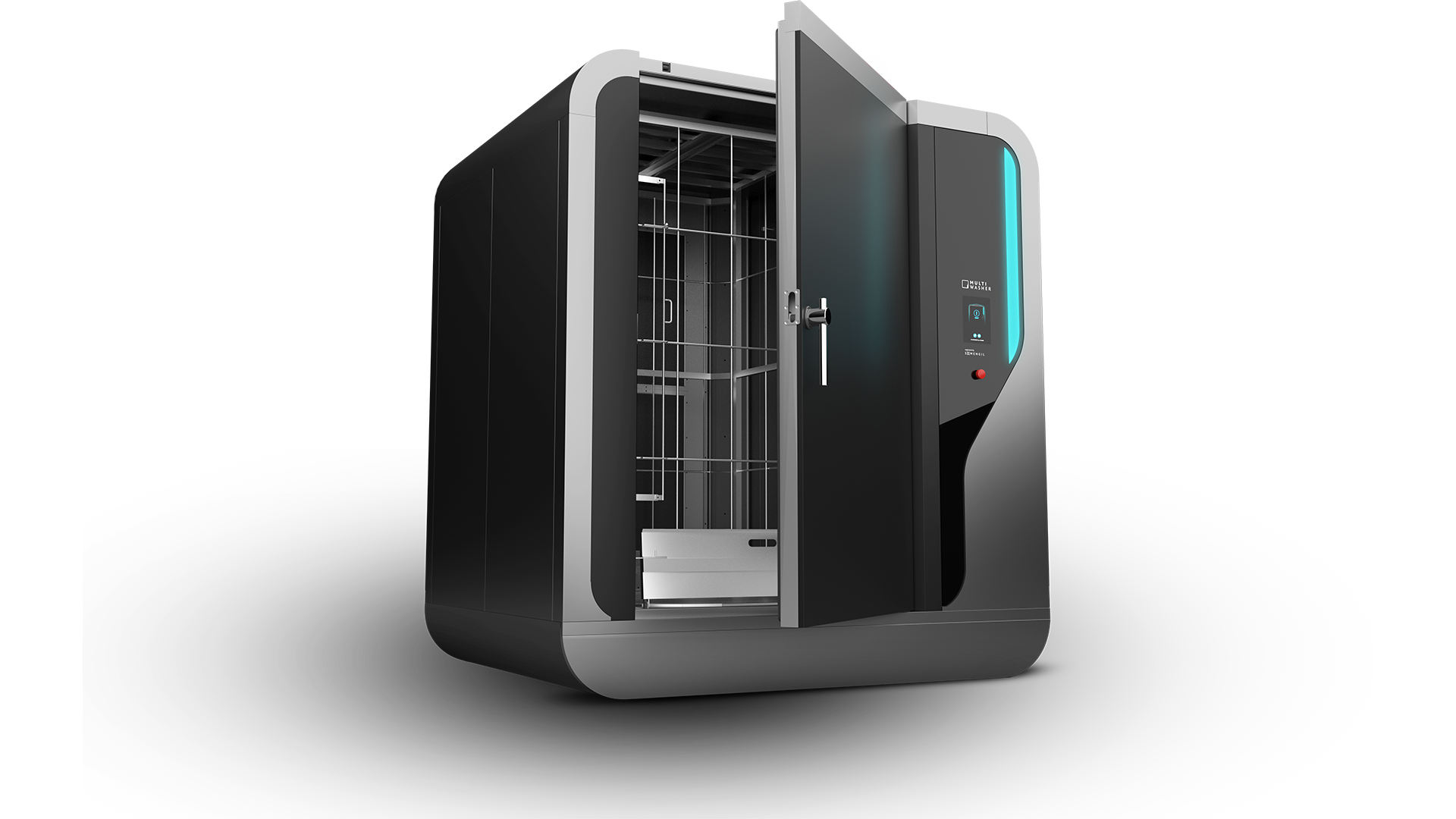

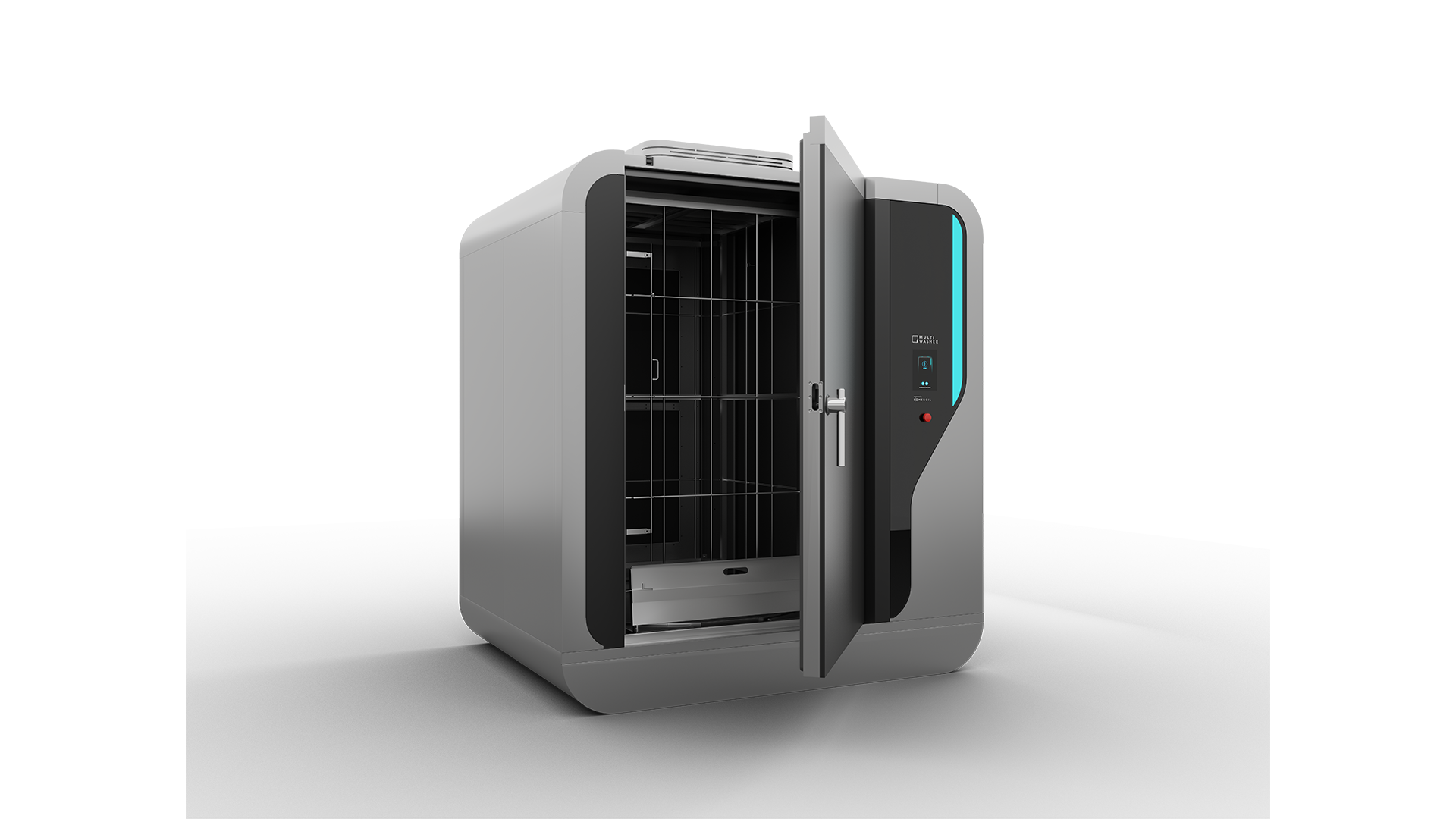

User-friendly operation

Rack washers may be powerful, but they are surprisingly easy to operate. MultiWasher, the industrial washing machine developed by Somengil, features intuitive control systems that allow users to start a wash with just a few settings or button presses. Advanced features like programmable cycles and automated drying take the guesswork out of washing, allowing operators to focus on other aspects of the business. The simplicity of these machines means you can get reliable results every time, without needing specialized training or maintenance efforts.

Limitations of rack washers

As useful as rack washers are, they’re not without their limitations, and it’s worth being upfront about them if you're considering one for your operation.

First, these machines are often designed with a specific type or size of rack in mind. That means flexibility can sometimes be an issue. If your operation uses a mix of carts, trays, or containers, you might need different settings, accessories, or even separate systems. Not all washers are ready to adapt, although MultiWasher is specifically built to accommodate more complex and diverse workflows.

There’s also the question of space and setup. Rack washers are typically large units that require proper infrastructure: plumbing, drainage, energy supply, ventilation. In tight or older facilities, installation can be a challenge. And like any advanced equipment, they need regular maintenance to stay efficient. The upside? Some solutions, like MultiWasher, have been developed with these challenges in mind, offering more compact designs, easier integration, and lower maintenance demands.

In short: rack washers do their job incredibly well, when you find the right fit. The key is choosing a solution built to work with your reality.

How rack washers work

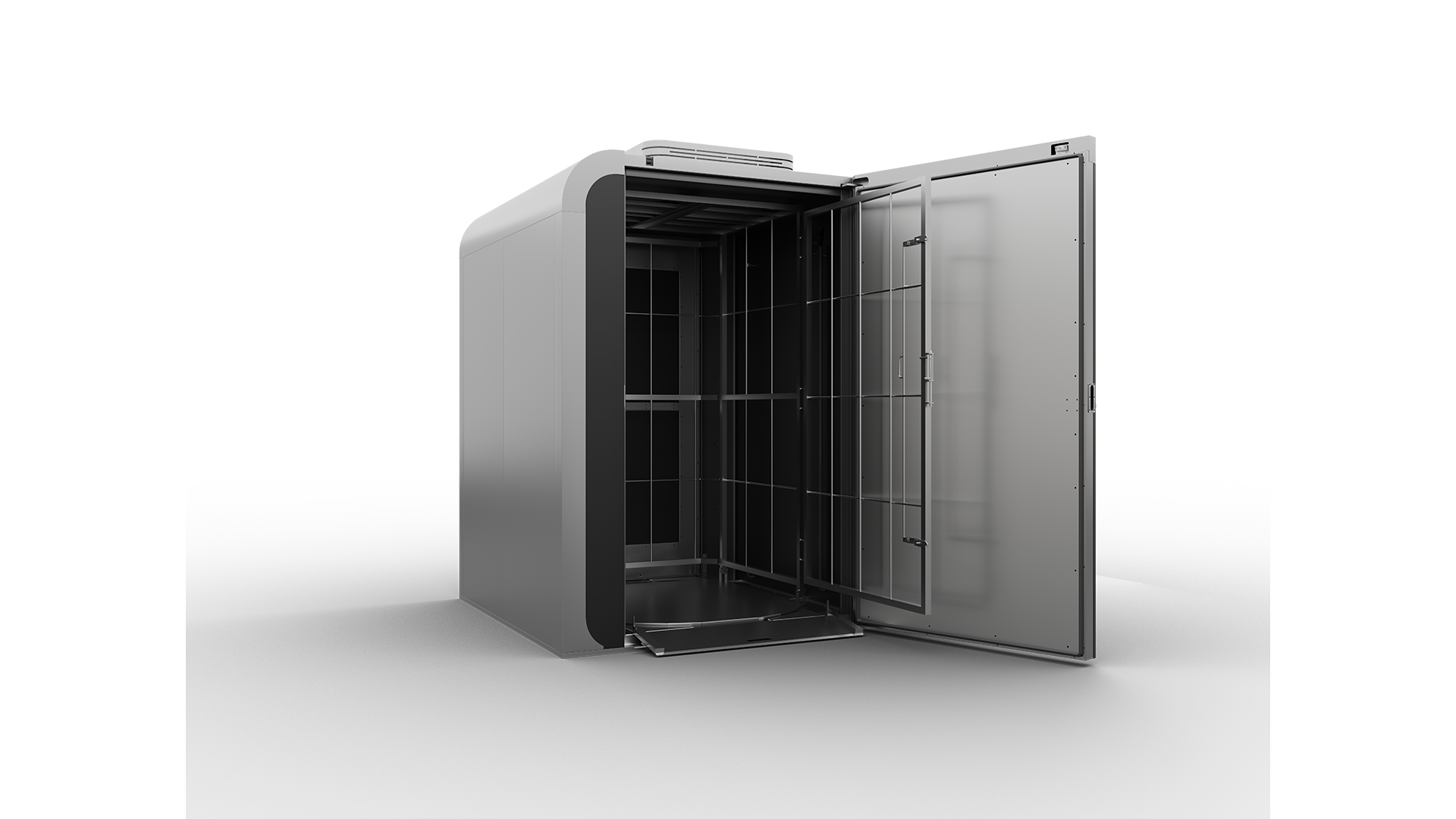

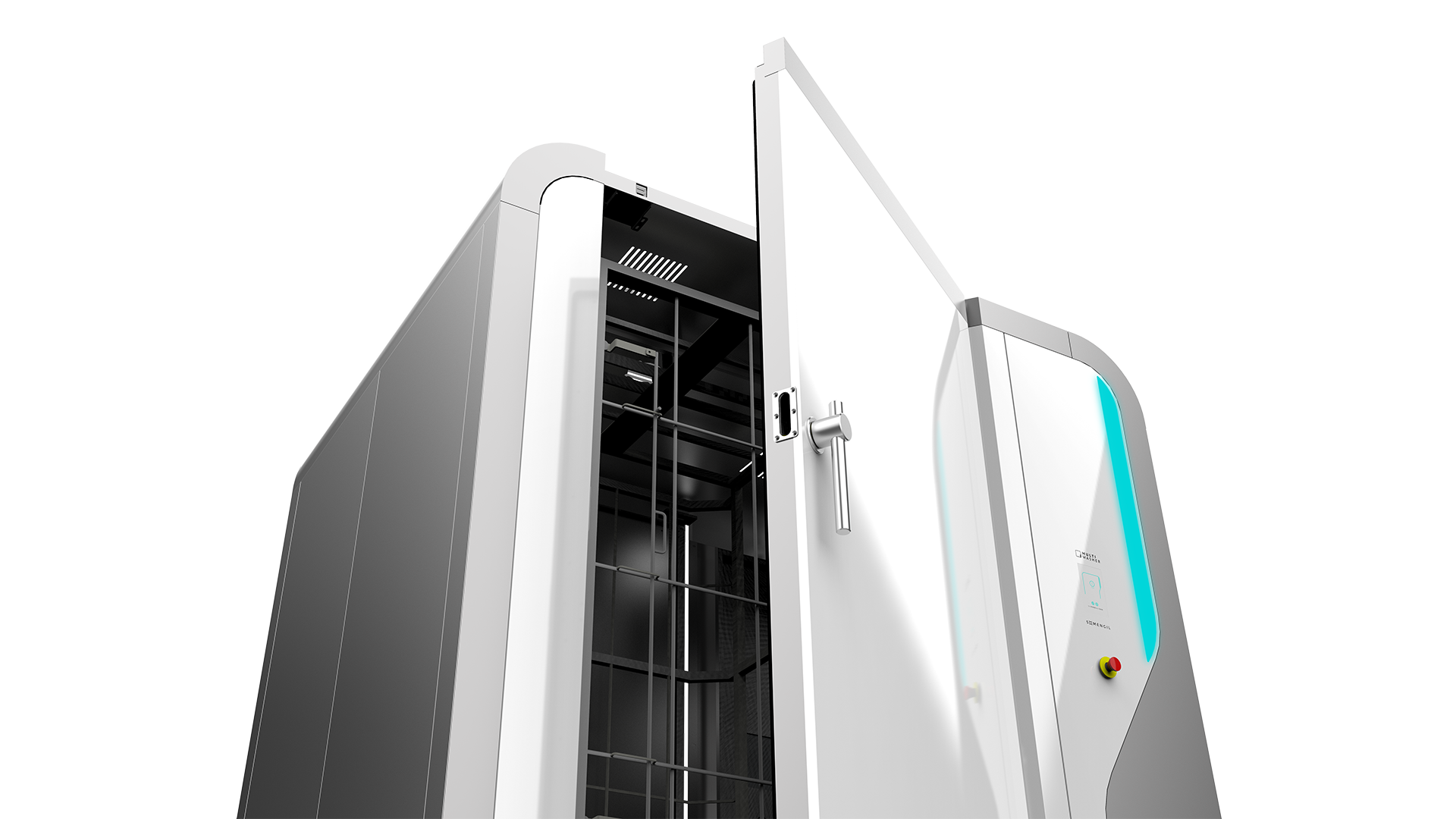

Rack washers might look like big, boxy machines, but what happens inside is all about precision, efficiency and hygiene.

At a basic level, the process is simple: you load your racks, carts or trays into the chamber (usually via a built-in track or rolling system), choose the right cycle, and let the machine handle the rest. High-pressure nozzles spray hot water and detergent from multiple angles, ensuring that every surface is reached, even in hard-to-wash corners. Some models also use rotating arms or oscillating jets to boost coverage and intensity.

After the wash, a rinse cycle removes detergent residue, followed by a disinfection phase (often using heat or chemical agents, depending on your needs). Most systems end with a drying step (either forced air or residual heat) so your equipment comes out washed, safe and ready to use.

What makes all the difference is customisation. With advanced systems like MultiWasher, you can fine-tune temperature, pressure, duration, and even drying settings to match the type of load you’re washing, whether it’s delicate baking trays or heavy-duty meat containers. It’s all about doing it right, every time.

Which companies are rack washers meant for?

If your business relies on reusable equipment that needs to be consistently washed and compliant with hygiene standards, a trolley or rack washer might be exactly what you need. These machines are built to serve a wide range of industries, and for good reason.

- Food and beverage processing: Ideal for removing grease, food residue, and bacteria from trays, carts, and racks, while meeting strict sanitation standards.

- Healthcare and pharmaceuticals: Critical for sterilizing transport equipment and minimizing cross-contamination in sensitive environments.

- Hospitality and catering: Perfect for quickly turning over service carts and kitchen racks between events or meal services.

- Industrial manufacturing: Useful for washing tools, parts, and carriers used in production lines, keeping everything in top condition.

- Logistics and distribution: Ensures that reusable containers and trolleys are washed and ready for safe transport across facilities.

What technologies go into trolley and rack washers?

While operating a rack washer might be as simple as pressing a button, there’s powerful technology working behind the scenes to make that simplicity possible. Today’s top machines, like MultiWasher, are packed with smart features that combine performance with efficiency.

- High-pressure water jets: Strategically positioned to reach all surfaces — even hidden corners — for a complete wash.

- Customizable wash cycles: Allow different settings for various items, levels of soil, or hygiene requirements.

- Energy- and water-saving systems: Including heat recovery, water recirculation, and eco wash modes that cut utility usage without sacrificing performance.

- Automated drying options: From heated air to condensation drying, ensuring equipment is dry, clean, and ready for immediate use.

- Touchscreen control panels: With intuitive interfaces, multiple language support, and user-friendly navigation.

- Built-in diagnostics: That monitor system performance and alert operators to maintenance needs before problems arise.

Signs you might need a rack washer

If you’re not sure whether a rack washer is something your facility actually needs, a few common signs can help point you in the right direction.

1. Manual washing is eating up your team's time

If staff are spending hours every day scrubbing trays, trolleys, or containers, it’s a red flag. That’s time they could be using on tasks that actually move the business forward. A rack washer standardises the process, cuts labour costs, and gives your team space to focus where they’re needed most.

2. Hygiene results are inconsistent (or unreliable)

Hand washing might feel “good enough”, but it’s hard to guarantee consistent results, especially when it comes to bacteria, allergens or residue buildup. If you’ve had close calls during audits or are unsure about what’s truly washed, a rack washer gives you control and peace of mind. Machines like MultiWasher are calibrated for repeatable, validated hygiene cycles.

3. Cleaning is creating bottlenecks

Are racks piling up waiting to be washed? Are your teams having to wait before the next load can go out? These delays may seem small, but over time they slow everything down: production, packing or logistics. Rack washers remove that friction by keeping your washing flow in sync with operations.

4. Water and energy bills are creeping up

Surprisingly, manual washing or outdated washing systems often use far more water, detergent and energy than a modern industrial washer. If your utility bills are climbing (or you’re under pressure to reduce consumption), a high-efficiency unit can help you meet sustainability goals and cut waste.

5. Equipment is getting damaged during cleaning

When racks and containers are washed manually or in machines not designed for them, it’s easy for parts to get bent, scratched or worn out too quickly. That means more frequent replacements and extra cost. Rack washers are built to handle these items gently but effectively, extending the lifespan of your equipment.

6. You're scaling up and the current setup can't keep up

Maybe things were working fine a year ago, but as volumes grow, so do the washing demands. If you’re processing more units, handling multiple shifts, or entering more hygiene-sensitive markets, your current setup might not be future-proof. A rack washer helps you scale without compromising standards.

How to choose the right rack washer

By focusing on a few key factors, you can make sure you're getting the best machine for your specific needs.

1. Capacity: matching the machine to your workflow

When selecting a rack washer, one of the most important factors to consider is the machine’s capacity. Start by assessing the number of items your business needs to wash daily. A machine with a larger capacity can handle more racks per cycle, which is essential for operations running around the clock or processing high volumes of equipment.

If your facility regularly experiences peak washing times, a high-capacity washer will prevent bottlenecks, allowing you to maintain a smooth workflow. On the other hand, if your cleaning needs are smaller or more sporadic, a medium-sized machine might suit your business better. Always aim to balance capacity with demand to avoid unnecessary operating costs or idle equipment.

2. Washing requirements: consider industry standards and specific needs

Different industries have different washing requirements, and it's vital to choose a rack washer machine that meets the specific standards of your sector. For example, healthcare facilities and food production plants often have stricter sanitation regulations, requiring machines that can disinfect items thoroughly. A rack washer with higher temperatures, stronger water pressure, or built-in disinfectant options might be necessary in these cases. Additionally, consider whether your equipment has unique cleaning challenges – such as delicate components, hard-to-reach areas, or particularly tough grime - that require specialized washing functions.

3. Energy efficiency: balancing performance and operating costs

More than just a buzzword, energy efficiency is a critical factor that directly affects your business’s operational costs. Look for a rack washer that balances powerful cleaning with minimal energy and water consumption. Machines with energy-efficient technologies, like MultiWasher, can significantly reduce your utility bills over time. Features like low-water wash cycles, energy-saving modes, and heat recovery systems are all worth considering. While energy-efficient models may have a higher initial price tag, the savings you’ll gain through reduced electricity and water use can quickly offset that.

4. Ease of use: streamlining daily operations

In any busy industrial environment, having equipment that’s easy to operate can make a big difference in your day-to-day efficiency. When choosing a rack washer, pay attention to how intuitive its controls are. Is it simple enough for your team to use without extensive training? Does it have customizable settings that let you adjust wash cycles for different items, or automated features that reduce the need for manual input? User-friendly machines reduce the chance of operator error and also save time during busy periods. MultiWasher even allows you to program multiple wash cycles, enabling you to tailor each cycle to specific cleaning needs with just the press of a button.

5. Durability and maintenance: investing in longevity

Rack washers are an investment, so it’s essential to choose a model that will stand the test of time. Durability is key in industrial environments where machines are expected to run frequently, sometimes around the clock. Look for rack washers built from high-quality materials like stainless steel, which can withstand the wear and tear of daily use, high temperatures, and constant exposure to water and cleaning chemicals.

Additionally, check what kind of maintenance the machine requires. Models featuring self-cleaning capabilities, combined with built-in diagnostics, can minimize downtime and help maintain the washer in optimal condition for years to come. A machine that’s durable and easy to maintain will not only last longer but also save you money on repairs and replacements. All these are some of the MultiWasher main attributes that are making a difference in all industries.

6. Support: reliable after-sales service matters

Even the best machines will require some level of support or maintenance throughout their lifespan, so it's crucial to choose a rack washer machine backed by strong customer service and technical support. Before making a purchase, check whether the manufacturer or supplier offers ongoing support, such as installation assistance, training for your staff, and regular maintenance services. Knowing that help is readily available when you need it ensures that your operations won’t come to a halt due to technical issues.

How to maximize the lifespan of your rack washer?

Like any industrial equipment, your rack washer is a long-term investment — and with the right care, it will deliver reliable performance for many years. Here’s how to keep it running at its best:

- Clean internal components regularly: Including filters, spray arms, and drainage systems, to prevent buildup and maintain water pressure.

- Use the machine correctly: Stick to recommended detergent types, follow the operating guidelines, and avoid overloading.

- Train your team: Proper usage reduces wear and tear and minimizes the risk of breakdowns caused by user error.

- Schedule preventive maintenance: Periodic checkups by certified technicians can catch small issues before they lead to bigger problems.

- Leverage smart diagnostics: Many modern washers include built-in monitoring that helps track usage and detect inefficiencies.

- Choose durable materials: Stainless steel construction and corrosion-resistant components offer better performance and longevity in tough environments.

Rack washers: frequently asked questions

Here are the answers to some of the most common questions about rack washers.

Are rack washers suitable for all types of racks and trolleys?

Most industrial washers, especially models like MultiWasher, are designed to handle a wide variety of shapes and sizes.

Do they require special installation?

Yes, professional installation is recommended to ensure proper water, drainage, and electrical connections. Somengil provides installation support to ensure everything works seamlessly from day one.

Can I wash different items in the same cycle?

Yes, as long as the items are compatible in terms of material and washing requirements. MultiWasher allows you to configure cycles that suit mixed loads.

What about noise levels?

Modern rack washers are designed with sound insulation and quiet operation in mind, making them suitable for use even in noise-sensitive environments.

Is technical support available after purchase?

Absolutely. Somengil offers comprehensive after-sales service, including training, maintenance, spare parts, and remote diagnostics.

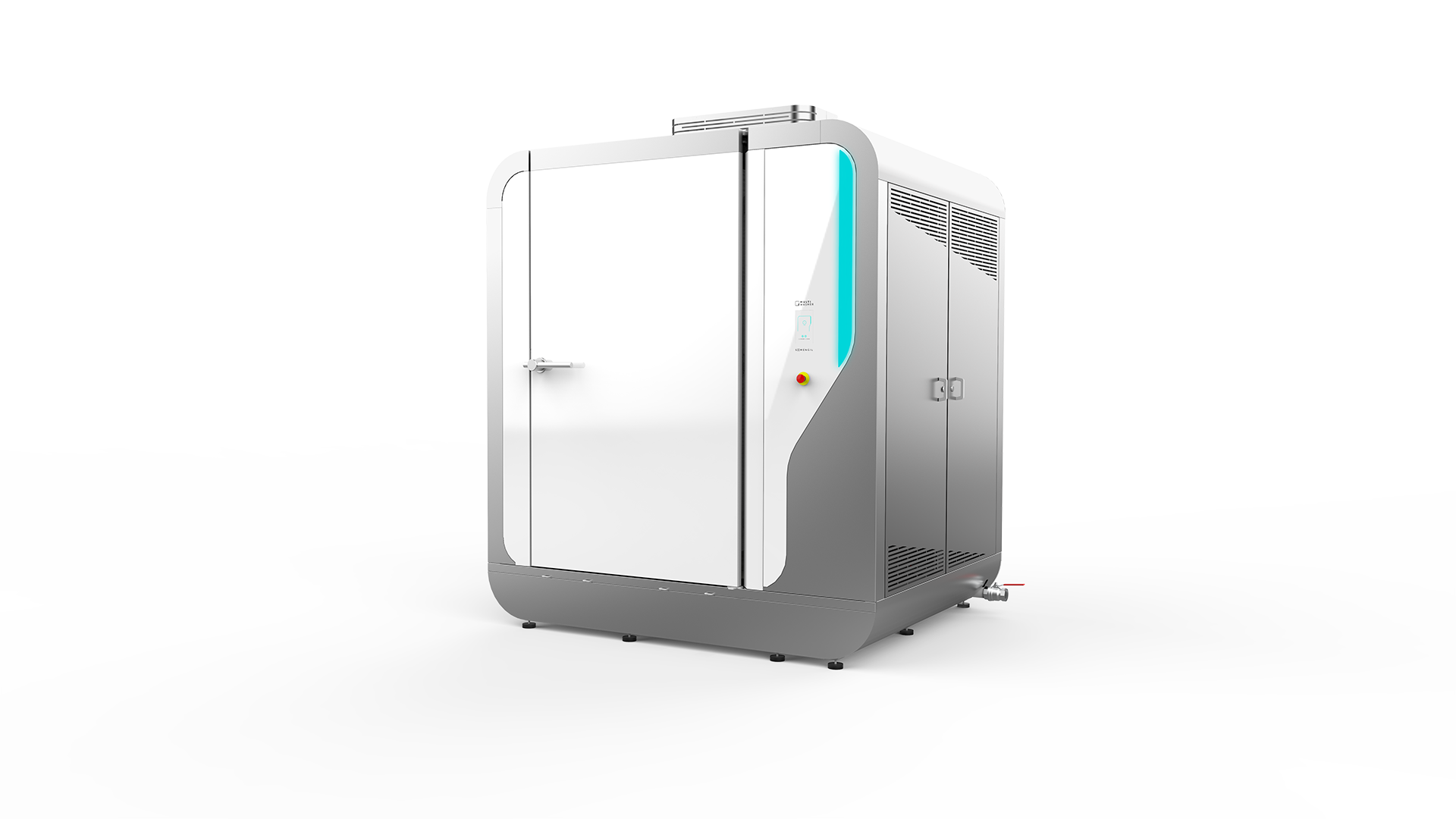

MultiWasher: the smart rack and trolley washer

From increased productivity to long-term cost savings, and from customizable features to reliable after-sales support, the right machine enhances your workflow and ensures compliance with the highest hygiene standards.

Ready to upgrade your washing process? MultiWasher offers cutting-edge technology, energy-efficient performance, and unmatched durability. Tailored for businesses that prioritize efficiency and hygiene, the MultiWasher is the rack and trolley washer that will save you time, money, and resources. Contact us today to learn how the MultiWasher can transform your washing operations.

You may also like

Industrial washing / Articles

Much more than AI: 5 major retail trends

Discover the 5 major retail trends that no company should miss out on, from Artificial Intelligence to sustainability.

Posted in 2024-01-03

Industrial washing / Articles

5 key trends from Anuga 2024

We were at Anuga, one of the major fairs in the food sector worldwide. Discover the 5 main trends that will shape the upcoming years.

Posted in 2024-05-07

Industrial washing / Articles

Multiwasher: Revolutionizing sanitation in the food industry

The Multiwasher is the world’s most innovative industrial washing machine that is increasing sanitation across many industries.

Posted in 2023-05-03

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew