Industrial washing / Articles

Pharmaceutical industry: how to choose the right industrial washing solution

In the pharmaceutical industry, industrial washing is a critical success factor. Find out how to choose the right equipment.

6 minutes of reading

6 minutes of reading

2024-03-08 14:24:34

Diethylene glycol is a highly toxic chemical normally used in cleaning products. But in 2022 it was detected in batches of cough syrup, with fatal consequences for 18 children. Production was halted and the license of the pharmaceutical company that produced the drug, Marion Biotech, has been suspended to this day.

Cases like this, although rare, show how important washing can be in the pharmaceutical industry. The chemicals used to replace a rigorous high-temperature process are often toxic and, if not properly removed, can be harmful to human health. In situations like the one at Marion Biotech, they proved fatal – for people and for the organization.

Professionals in the sector know this well: whenever processes involve handling active ingredients, sanitization should be a priority. Any residue can, over time, develop bacterial colonies that contaminate the product and endanger public health. The question is how to choose the right equipment for the specific needs of each business. These are the main factors to consider.

1. Dimensions

It may seem surprising, but the way equipment fits in the available physical space is one of the last priorities for many managers when choosing an industrial washing machine. However, considering the space available in the facilities is critical to ensure efficient integration into the production environment. This also covers practical considerations related to accessibility for maintenance and cleaning.

2. Capacity

Assessing the machine’s capacity – both in volume and size of utensils to be washed – is key to the overall performance and efficiency. Dimensions must be adapted to the specific production requirements, avoiding possible bottlenecks in the production line.

3. Total cost

It’s tempting to put more emphasis on the upfront cost when choosing any piece of equipment. However, a better metric is its Total Cost, which goes beyond the initial price and includes all the associated costs throughout the equipment’s life cycle. Total cost considers operating and maintenance costs associated with possible downtime. A more expensive machine at the start could save money on operating costs over time, or vice versa.

In addition, the efficiency of the machine is obviously very important and should be added to the Total Cost. Machines that consume less energy, water and detergent reduce running costs and contribute to more sustainable practices.

4. Materials

The choice of materials must be based on specific criteria to the pharmaceutical industry. Non-reactive materials are essential to avoid any unwanted interaction between cleaning chemicals and machine components. In addition, corrosion resistance is essential for long-term durability, especially since machine parts are exposed to chemicals during washing processes.

5. Versatility

Industrial washing machines for the pharma industry must be capable of deep, thorough and efficient cleaning of all types of utensils – like parts, tools, bins, trays, containers or trolleys. In other words, washing equipment must achieve and maintain the ideal temperature, pressure and cycle time parameters to ensure the microbiological integrity of the equipment and, consequently, the products.

6. Customer support

In addition to the technical characteristics of the machine itself, it is important to consider the experience associated with the brand that manufactures it. In the pharmaceutical industry, where regulatory compliance is crucial, having access to effective technical support and reliable maintenance services ensures continuous operation and long-term compliance.

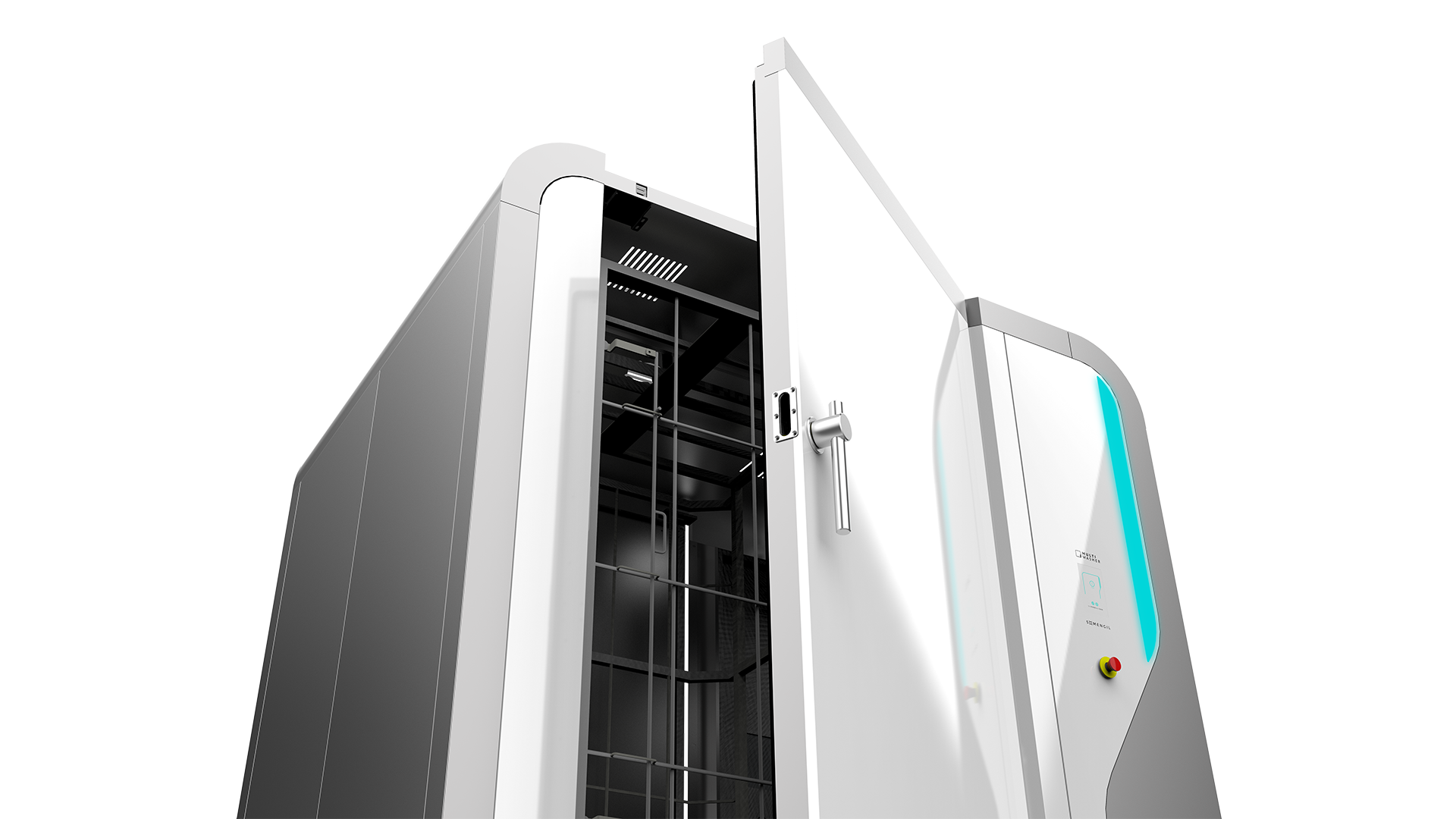

7. Ergonomics

When choosing an industrial washing solution for the pharmaceutical industry, ergonomics plays a key role. Ease of use is a crucial aspect to ensure that operators interact with the machine intuitively. A user-friendly interface, well-positioned controls and easy-to-operate screens contribute to smooth and efficient processes. In addition, concern for operator safety is essential, minimizing the risk of injury and creating a positive work environment.

8. Flexibility

The only way to achieve a truly productive washing process is to adapt parameters such as temperature, water pressure and duration to the needs of each load. The ability to program specific cycles and keep the selected settings consistent over time contributes to operational efficiency and consistent wash quality.

9. Design

The machine must be designed for safety – including the prevention of contamination – and to facilitate the washing process. For example, smooth surfaces, with no hard-to-reach corners, are essential to avoid the agglomeration of residues and micro-organisms. Efficient drainage systems must also be considered to prevent leaks, water accumulation, and the formation of microbiota.

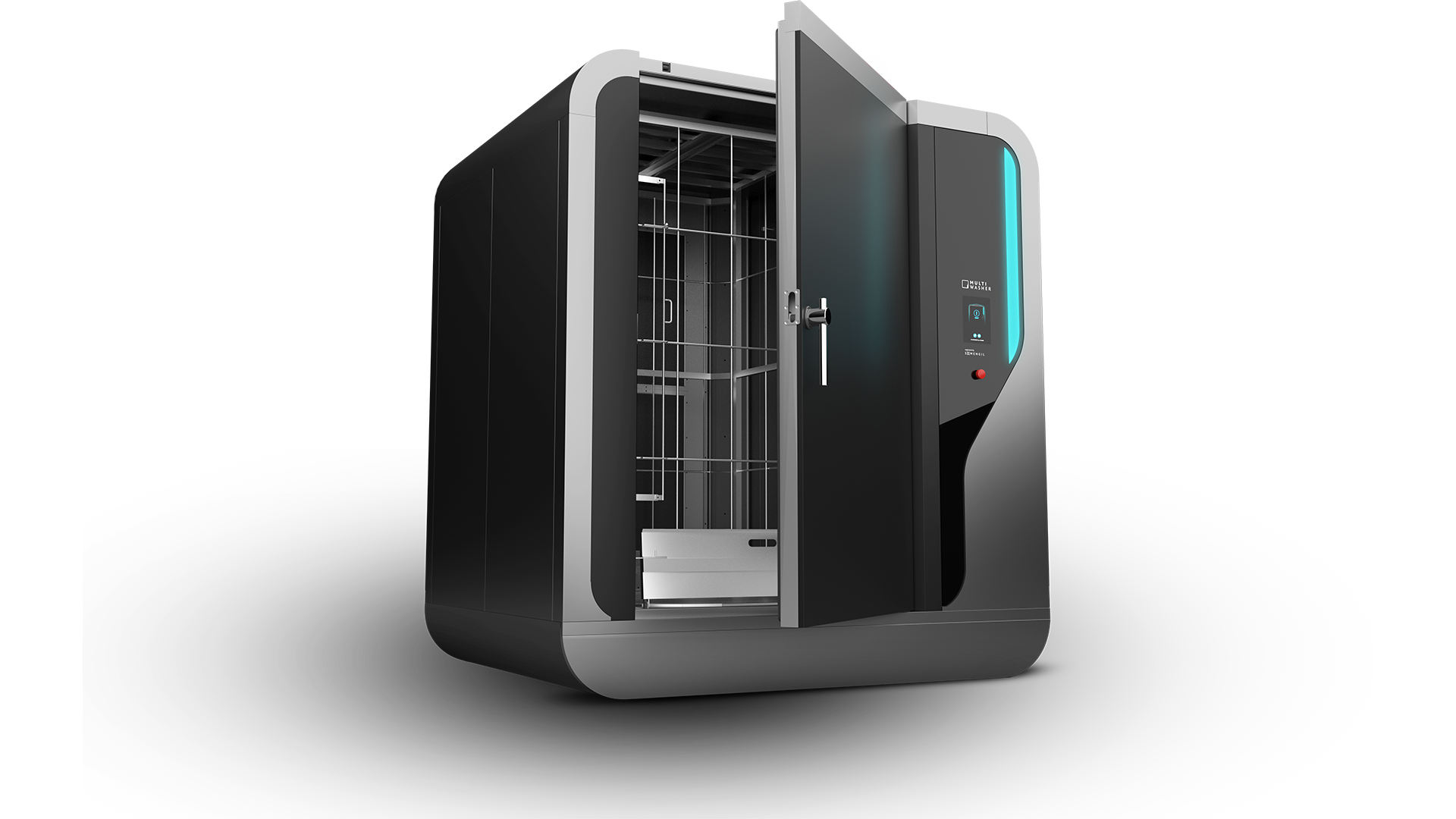

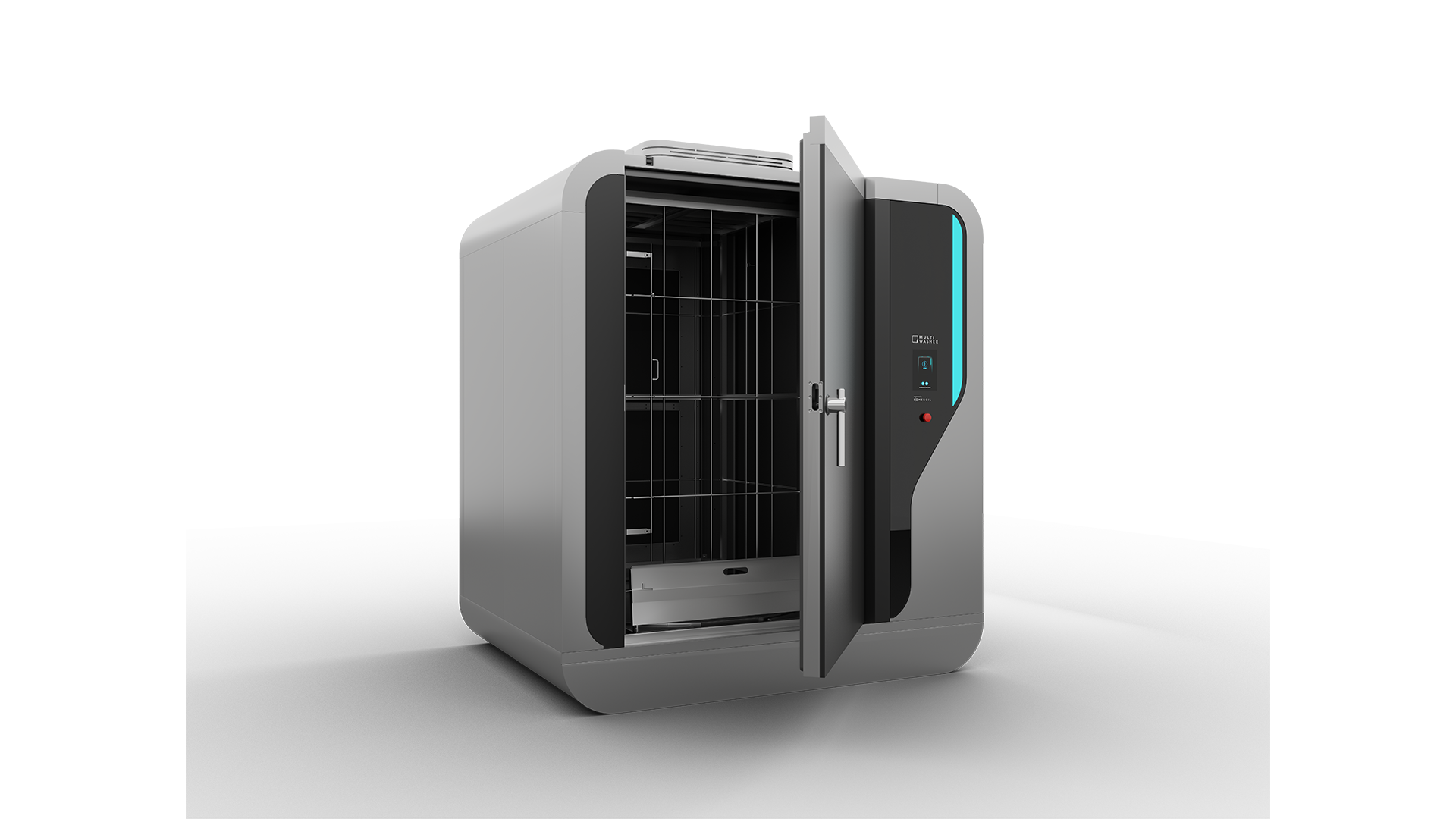

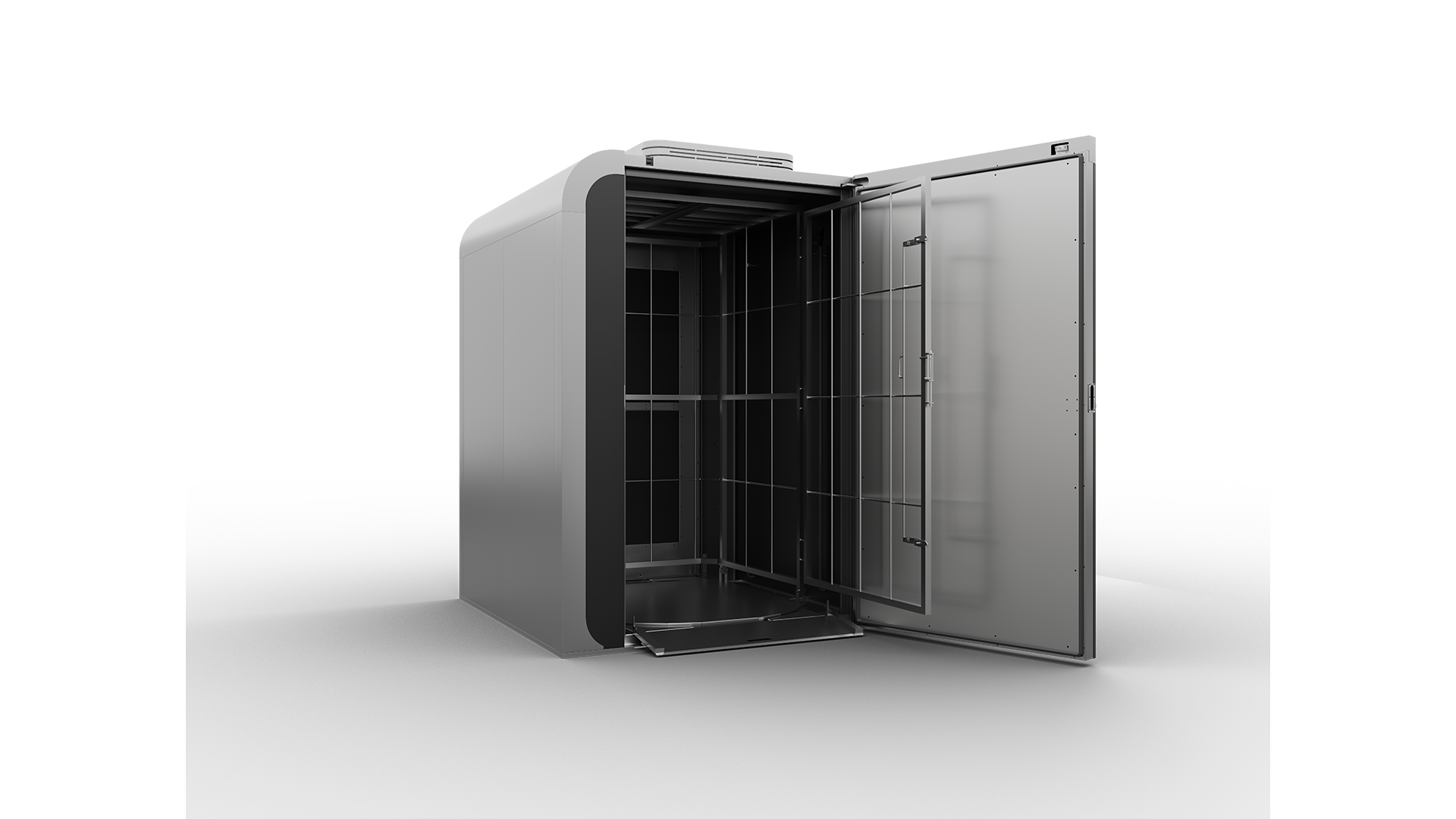

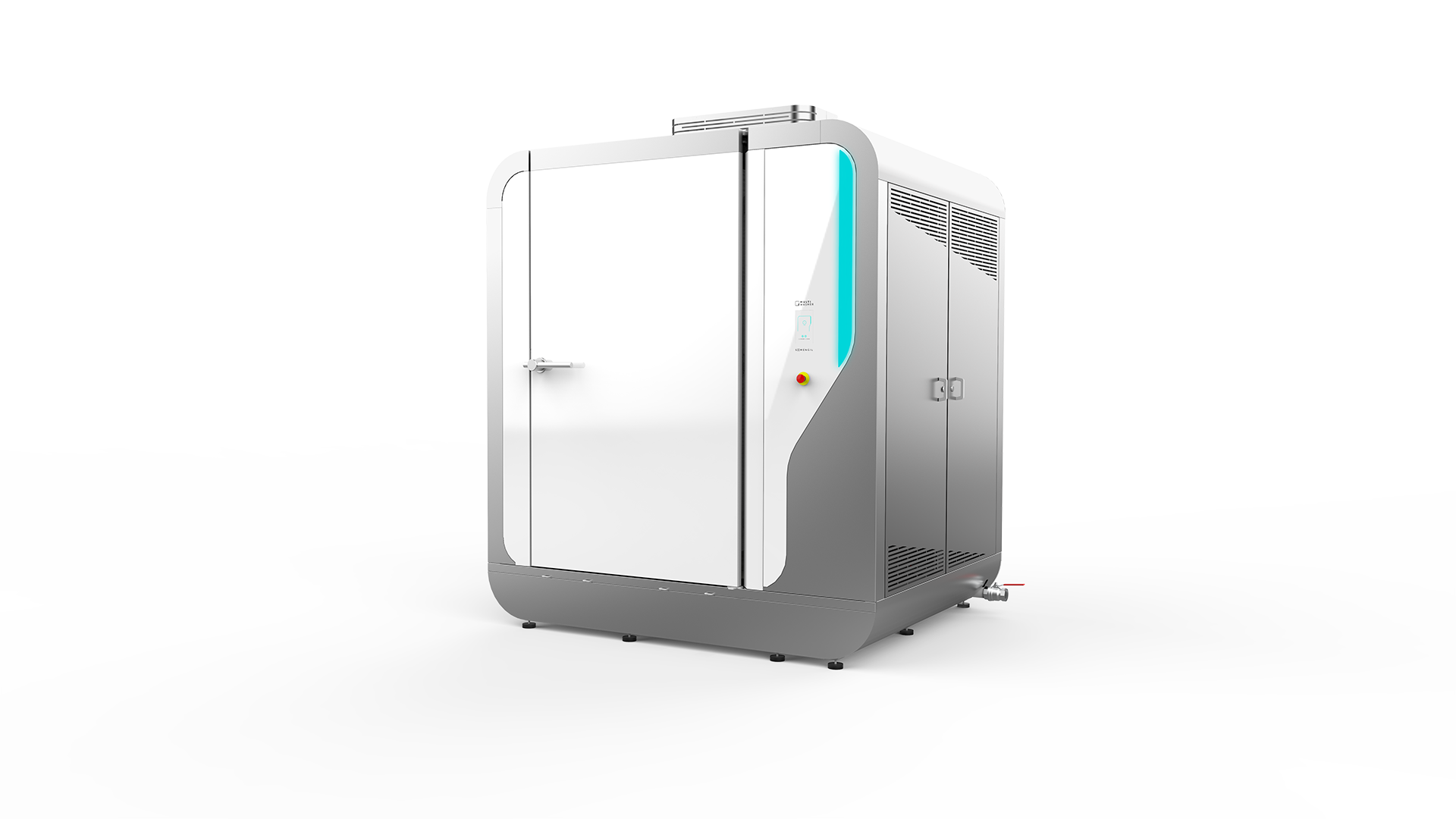

MultiWasher, the industrial washing machine for the pharmaceutical industry

The MultiWasher is a state-of-the-art industrial washing machine that washes trays, boxes, multi-headers and many other indispensable tools and utensils for the pharmaceutical industry. It can be designed according to the standards of each company and customized according to the needs of the installation. Get in touch with our team of experts and see how MultiWasher can help ensure compliance with the pharmaceutical industry’s most demanding hygiene criteria.

You may also like

Industrial washing / Articles

Meat industry washer: your key to safer, smarter meat processing

Learn what meat industry washers are and when they become a critical investment for hygiene and efficiency.

Posted in 2025-09-16

Industrial washing / Articles

“Even the most advanced companies can save up to 70% of water. Here’s how”

We spoke with Renato Gomes, Somengil’s Sales Manager for the Americas, who has seen first-hand how much companies can save – and the pitfalls to...

Posted in 2024-04-23

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew